Manual handling hazards are one of the leading causes of workplace injuries in Australia, contributing to musculoskeletal disorders (MSDs), fatigue, and long-term health risks. From lifting and pushing to repetitive movements and awkward postures, these everyday tasks can quickly become hazardous when done unsafely.

Understanding the different types of manual handling hazards is essential for employers, workers, and WHS managers who want to prevent injuries, comply with safety legislation, and build healthier workplaces. Identifying risks early and applying practical controls can reduce injury rates, improve productivity, and support long-term worker wellbeing.

Manual handling hazards refer to workplace activities that involve lifting, carrying, pushing, pulling, holding, or restraining objects, people, or animals. These tasks may seem routine, but when they involve repetitive strain, excessive force, or poor technique, they can cause serious injuries such as sprains, strains, fractures, and long-term musculoskeletal disorders (WMSDs).

In Australia, hazardous manual tasks are recognised under workplace health and safety (WHS) laws because of their high risk for injury. Employers have a legal duty to identify, assess, and control these hazards to keep workers safe. Workers also have a responsibility to follow safe practices and report risks when they arise.

Understanding the different types of manual handling risks and how they occur can help organisations implement targeted injury prevention strategies. Proactively addressing these hazards reduces claims, downtime, and healthcare costs while promoting a safer, healthier workplace.

Not all manual handling tasks carry the same level of risk. Workplace health and safety (WHS) guidelines highlight specific hazard categories that contribute most to injuries. These risks should be identified early, allowing employers to take proactive measures such as implementing structured manual handling training. Doing so helps lower injury rates and contributes to a safer, more efficient workplace.

Repetitive tasks, such as constant lifting, bending, or twisting, place stress on the same muscle groups and joints. Over time, this can result in cumulative strain injuries and long-term musculoskeletal disorders. In fact, repetitive strain is one of the most common workplace injuries in Australia, often linked to unsafe manual handling techniques.

It is classified as a repetitive movement hazard, a specific kind of manual handling hazard that arises when workers perform the same actions repeatedly without adequate breaks or ergonomic support.

Common examples include packing boxes on a production line, repetitive scanning at checkouts, or continuous data entry with poor ergonomics. These tasks highlight how repetitive movement becomes hazardous when the body is subjected to ongoing strain, especially in environments where safe handling practices are not followed.

Applying sustained force, such as holding a heavy item for an extended period, or sudden force, like catching a falling object, can put significant strain on muscles, tendons, and ligaments. These types of physical exertion often result in acute injuries, including sprains, strains, or even fractures.

It refers to the continuous physical effort required to grip, carry, or support a load without taking breaks. This kind of prolonged exertion becomes especially hazardous when dealing with heavy or awkward items. When sustained force is combined with the sudden force injury risk of unexpected movements, the likelihood of harm increases significantly.

Practical examples include holding tools overhead for extended periods, suddenly pulling jammed equipment, or pushing a heavy trolley up an incline. Each of these scenarios demonstrates how both sustained and sudden forces can quickly escalate into serious manual handling hazards if not properly managed.

When workers operate in awkward or sustained postures, such as bending, twisting, reaching, or working above shoulder height, the spine and joints experience unnatural strain. Prolonged exposure increases the likelihood of chronic back pain, shoulder injuries, and neck disorders, making awkward posture hazards one of the most common causes of long-term musculoskeletal issues.

Both expose the body to continuous stress without proper recovery time, leading to fatigue, cumulative strain, and eventual injury. Awkward postures also make it harder for muscles and joints to function efficiently, which accelerates the damage caused by repetitive tasks. Implementing effective awkward posture control measures, such as ergonomic workstation design, use of adjustable equipment, or rotating job tasks, helps reduce these risks significantly.

Common examples include stocking shelves at high or low levels, working in confined spaces, or prolonged crouching on construction sites, all of which highlight how posture-related hazards contribute to workplace injuries if left unmanaged.

Exposure to vibration from power tools, machinery, or vehicles can cause serious long-term health issues if not properly managed. Whole-body vibration hazards typically come from operating equipment like forklifts or heavy vehicles, placing strain on the spine and increasing the risk of chronic back pain. Hand-arm vibration hazards, on the other hand, result from using tools such as jackhammers or handheld drills, which can damage circulation, grip strength, and nerve function.

The key distinction lies in how the vibration enters the body. Whole-body vibration spreads through the seat or platform and mainly affects the spine, while hand-arm vibration is transmitted directly through handheld tools and impacts the arms, hands, and fingers.

Examples include forklift drivers exposed to vehicle vibrations and construction workers using jackhammers or drills for extended periods. Without proper controls, both forms of vibration can lead to irreversible health conditions, making early prevention critical.

Injuries in manual handling aren’t always the result of heavy loads. Many stem from ergonomic risk factors in manual handling that place unnecessary stress on the body. Poor workplace design, unsuitable tools, and tasks that force the body into unsafe positions all contribute to workplace ergonomic hazards and increase the likelihood of work-related musculoskeletal disorders (WMSDs).

Some key ergonomic risk factors in manual handling include:

These are the most significant WMSD ergonomics risks that tend to cause chronic injuries if unmanaged.

Addressing ergonomic hazards requires more than quick fixes. It involves structured ergonomic assessments, redesigning workstations, introducing adjustable equipment, and rotating tasks to balance physical strain. Workplaces that invest in strong ergonomic practices not only reduce injury rates and compensation claims but also improve productivity, employee morale, and long-term safety outcomes.

To create safer workplaces, employers must move beyond raising awareness and take proactive steps by conducting structured risk assessments for hazardous manual tasks. A manual handling risk assessment involves identifying the task, evaluating the associated risks, and implementing practical control measures to reduce the chance of injury.

A strong risk assessment looks at:

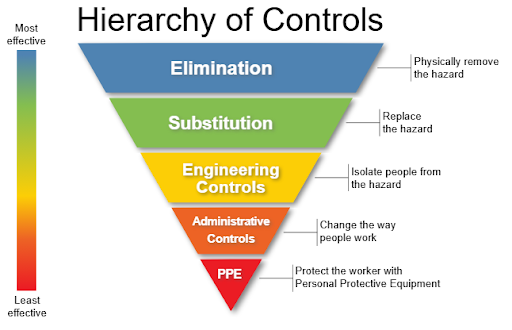

The answer lies in carrying out thorough risk assessments and applying the hierarchy of controls. According to WorkSafe guidelines on hazardous manual handling, controls should follow the hierarchy of risk management:

Employers also have a legal responsibility under WHS legislation to conduct these assessments and ensure ongoing compliance. Failure to do so can increase injury risks, compensation claims, and lost productivity.

At AusRehab, we help businesses carry out comprehensive workplace assessments to spot risks, ensure suitable duties align with workers’ capacity, and recommend workplace adjustments where needed to support long-term health, compliance, and a safe return to work for injured workers.

The most effective way to reduce manual handling injuries is through prevention. Instead of waiting for incidents to occur, employers and workers should focus on safe manual handling techniques and structured education programs that build long-term resilience.

Training in Safe Manual Handling Techniques

Practical, hands-on training ensures workers understand how to lift, carry, push, and pull safely. AusRehab delivers manual handling training in Sydney tailored to each workplace. Training can be customised to address high-risk tasks and industry-specific hazards, giving workers confidence to manage their roles safely. See how one of our clients reduced injury risk with training in this case study: Manual Handling Training with Future Form.

Applying Workplace Injury Prevention Strategies

Workers can lower injury risks by adopting injury prevention strategies in the workplace, such as using lifting aids, trolleys, or adjustable equipment. Rotating between tasks, redesigning workstations to reduce awkward reaches, and taking regular breaks all help minimise repetitive strain and fatigue.

Building a Safety-Focused Culture

A workplace that encourages open reporting, regular toolbox talks, and visible leadership commitment makes it easier for workers to practise safe habits daily. This culture ensures that safe manual handling techniques are reinforced consistently.

Using Ergonomics to Identify Risks

Practical ergonomic assessments help employers identify subtle risk factors, such as desk height, repetitive mouse use, or vibration exposure. Adjustments as simple as new seating, anti-fatigue mats, or ergonomic tools can drastically cut injury rates.

Even with the best prevention strategies, workplace injuries can still occur. When they do, effective workplace rehabilitation for manual handling injuries is crucial. AusRehab supports injured workers in their recovery while helping employers reduce costs and maintain business continuity.

Recovery from manual handling injuries requires a tailored plan that balances medical needs with workplace demands. Our accredited consultants develop structured programs that outline suitable duties, set rehabilitation goals, and define realistic timeframes. These return-to-work plans guide workers step by step in their return to work after a manual handling injury, ensuring both safety and productivity.

To prevent the risk of re-injury, AusRehab workplace assessments focus on the injured worker’s actual duties and environment. Our consultants identify barriers, recommend adjustments or equipment, and develop strategies that support a safe and sustainable return to work.

Learn more about what workplace rehab providers actually do in guiding injured employees back to safe and meaningful work.

Successful rehabilitation depends on collaboration. Employers, insurers, doctors, rehab provider, and other allied health professionals must all work together. A skilled rehabilitation provider helps manage communication, ensure compliance, and streamline processes.

See how RTW coordinators transform the workplace by making recovery a shared success.

Early intervention, open communication, and strong support systems are vital for long-term outcomes. Our team applies key strategies for successful return-to-work programs, ensuring that workers feel supported, employers stay compliant, and insurers benefit from more sustainable claim outcomes.

Manual handling hazards remain one of the leading causes of workplace injuries across Australia. These risks not only impact productivity but can also have long-term consequences on worker health and employer costs.

The good news? Most risks are preventable with the right strategies. Providing employees with manual handling training ensures they have the knowledge and techniques to perform tasks safely and efficiently. Ergonomic assessments are designed to match solutions to the unique demands of each role and work environment, helping create a workspace that boosts comfort, efficiency, and performance while reducing the risk of injury.

When injuries do occur, having a structured return-to-work program in place supports safe recovery and helps maintain workforce stability. At AusRehab, we partner with employers, insurers, and workers to build safer, healthier, and more resilient workplaces.

✅ Comprehensive manual handling training session

✅ Practical injury prevention strategies

✅ Workplace hazard identification & posture guidance

✅ Hands-on demonstrations for safe manual handling

📞 1800 991 614

📧 office@ausrehab.com

🔗 Book your Manual Handling Assessment with AusRehab and build a safer workplace today.

The main categories of manual handling hazards are: repetitive movements, sustained or sudden force, awkward postures, and vibration hazards. Each of these can significantly increase the risk of workplace musculoskeletal injuries if not properly managed.

An ergonomic risk assessment for lifting looks at factors such as weight, frequency of lifts, posture, reach distance, and environmental conditions. The goal is to identify unsafe practices and recommend controls like equipment use, job redesign, or manual handling training.

Ergonomics helps design tasks, workspaces, and equipment that fit the worker instead of forcing the worker to adapt to unsafe conditions. Ergonomic adjustments, such as height-adjustable desks, mechanical aids, and task rotation, reduce strain and prevent injuries.

Employers can reduce ergonomic hazards through:

Conducting regular ergonomic assessments to spot risks early

Repetitive and forceful movements are classified as musculoskeletal disorder hazards. These can lead to injuries such as sprains, strains, and repetitive strain injuries (RSIs), which are among the most common workplace injuries in Australia.

Repetitive strain injury is typically caused by tasks that involve repeated movements, prolonged awkward postures, or sustained force without adequate rest breaks. Employers can reduce risk by rotating tasks, ensuring ergonomic work design, and encouraging early reporting of symptoms.

Yes. AusRehab offers tailored manual handling training programs designed to equip workers with safe techniques for lifting, carrying, and performing physical tasks. We also conduct comprehensive workplace assessments, including ergonomic assessments, to identify risk factors and recommend practical solutions that help prevent injuries and support recovery. These services are part of our commitment to creating safer, more efficient work environments for both employees and employers.

AusRehab provides comprehensive support to help injured workers transition back to the workplace safely and confidently. We develop tailored return-to-work (RTW) plans based on the worker’s condition and job requirements, ensuring the recovery process aligns with medical advice and workplace capabilities. Our team coordinates closely with treating doctors, employers, and insurers to facilitate effective communication and planning.

Don’t forget to share!

Subscribe to stay updated on the latest workplace news.

Resolve your work

place injury today